Automatic Notch Aligners

WHS-A3 Series

Aligner Automatic Notchfinder

얼라이너 자동 노치파인더

Wafer Size: 6" 8"

-Type:Automatic

-25 slot

재질

스테이지:정전기 방지 폴리옥시메틸렌

롤러:정전기 방지 폴리우레탄

|

|

|

|

Alignment - 웨이퍼 플랫 및 노치 정렬기는 반도체 산업에서 리소그래피, 증착, 에칭과 같은 다양한 공정 중에

웨이퍼의 방향이 올바른지 확인하는 데 사용됩니다.

플랫 얼라이너는 웨이퍼의 결정 격자 구조의 방향에 해당하는 노치 또는 플랫을 가지고 있습니다.

웨이퍼의 방향이 최종 반도체 장치의 성능과 기능에 영향을 미치기 때문에 이는 매우 중요합니다.

웨이퍼의 방향이 올바른지 확인하는 데 사용됩니다.

플랫 얼라이너는 웨이퍼의 결정 격자 구조의 방향에 해당하는 노치 또는 플랫을 가지고 있습니다.

웨이퍼의 방향이 최종 반도체 장치의 성능과 기능에 영향을 미치기 때문에 이는 매우 중요합니다.

로트 무결성- 정렬기는 반도체 산업에서 운영자가 로트 무결성 검사를 수행하는 데 도움을 주기 위해 사용되기도 합니다.

작업자가 볼 수 있도록 웨이퍼 가장자리의 식별 표시인 웨이퍼 스크라이브를 회전시킴으로써 작업자는

올바른 로트의 웨이퍼가 생산 도구에 로드되고 있는지

확인할 수 있습니다.

이는 오류를 방지하고 일관된 제품 품질을 보장하는 중요한 단계입니다.

Edge inspection(가장자리 검사)- 웨이퍼 플랫 및 노치 정렬 장치는 반도체 산업에서 웨이퍼의 가장자리 결함을 검사하는 데에도 사용됩니다.

이 매크로 검사 절차는 일반적으로 광원 아래에서 수행되며 웨이퍼 가장자리에 칩, 균열 또는 기타 결함이 있는지 검사하는 작업이 포함됩니다.

이는 후속 처리 단계에서 웨이퍼 파손을 방지하는 중요한 단계입니다. 가장자리 결함으로 인해

웨이퍼가 약해지고 파손되거나 실패할 수 있기 때문입니다.

웨이퍼 플랫 및 노치 정렬 장치를 사용하여 이러한 결함을 식별하고 검사함으로써

작업자는 결함이 있는 웨이퍼의 추가 처리를 방지하고 비용이 많이 드는 생산 지연을 방지하기 위한 조치를 취할 수 있습니다.

이 매크로 검사 절차는 일반적으로 광원 아래에서 수행되며 웨이퍼 가장자리에 칩, 균열 또는 기타 결함이 있는지 검사하는 작업이 포함됩니다.

이는 후속 처리 단계에서 웨이퍼 파손을 방지하는 중요한 단계입니다. 가장자리 결함으로 인해

웨이퍼가 약해지고 파손되거나 실패할 수 있기 때문입니다.

웨이퍼 플랫 및 노치 정렬 장치를 사용하여 이러한 결함을 식별하고 검사함으로써

작업자는 결함이 있는 웨이퍼의 추가 처리를 방지하고 비용이 많이 드는 생산 지연을 방지하기 위한 조치를 취할 수 있습니다.

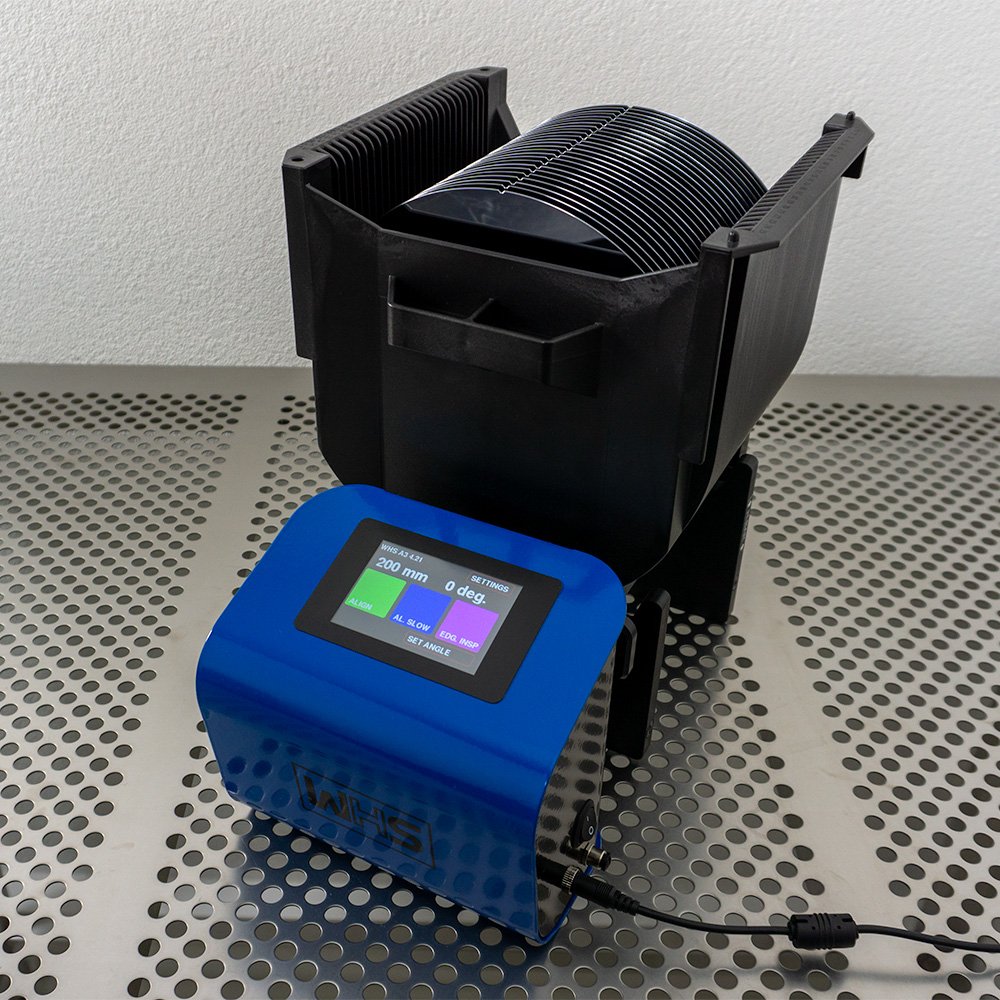

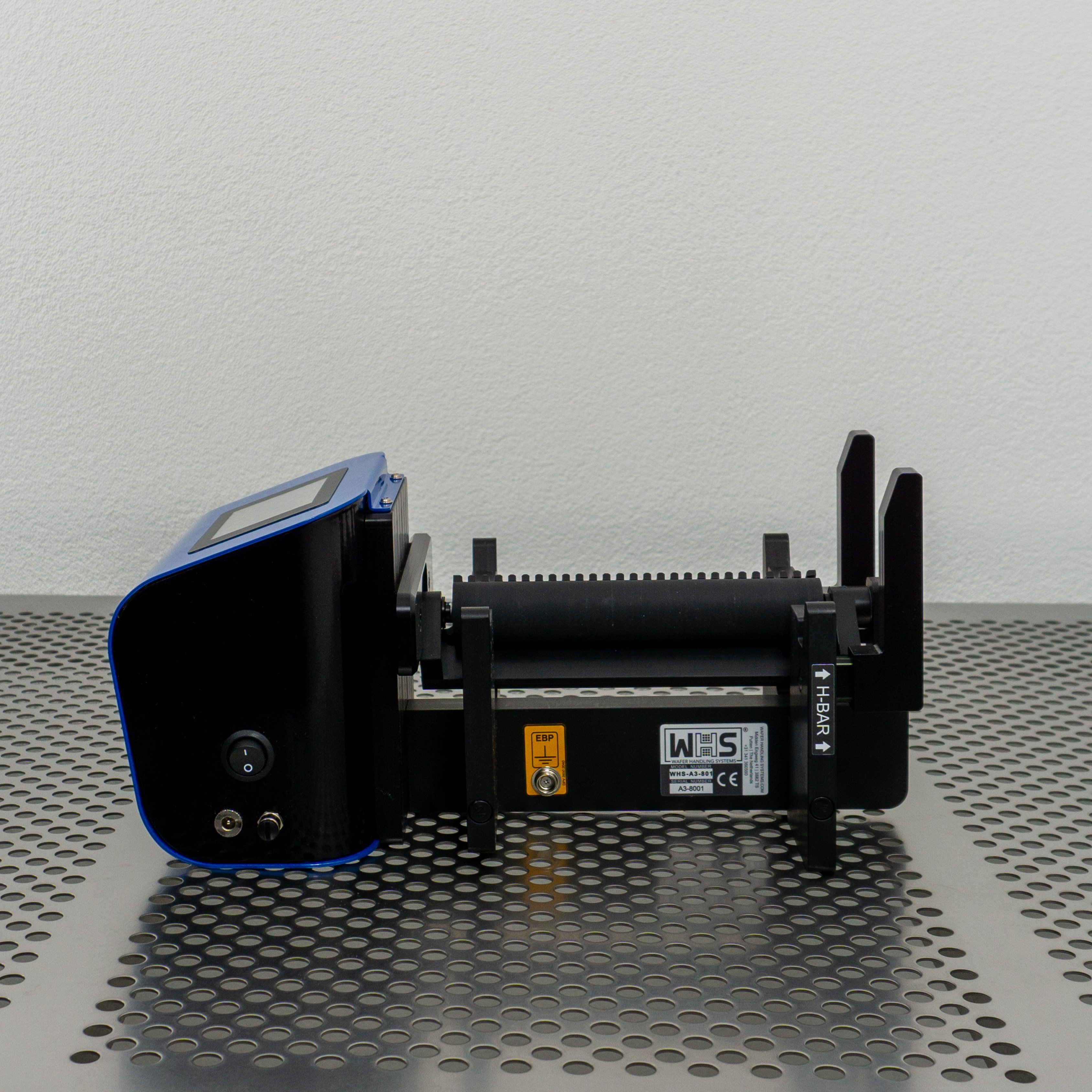

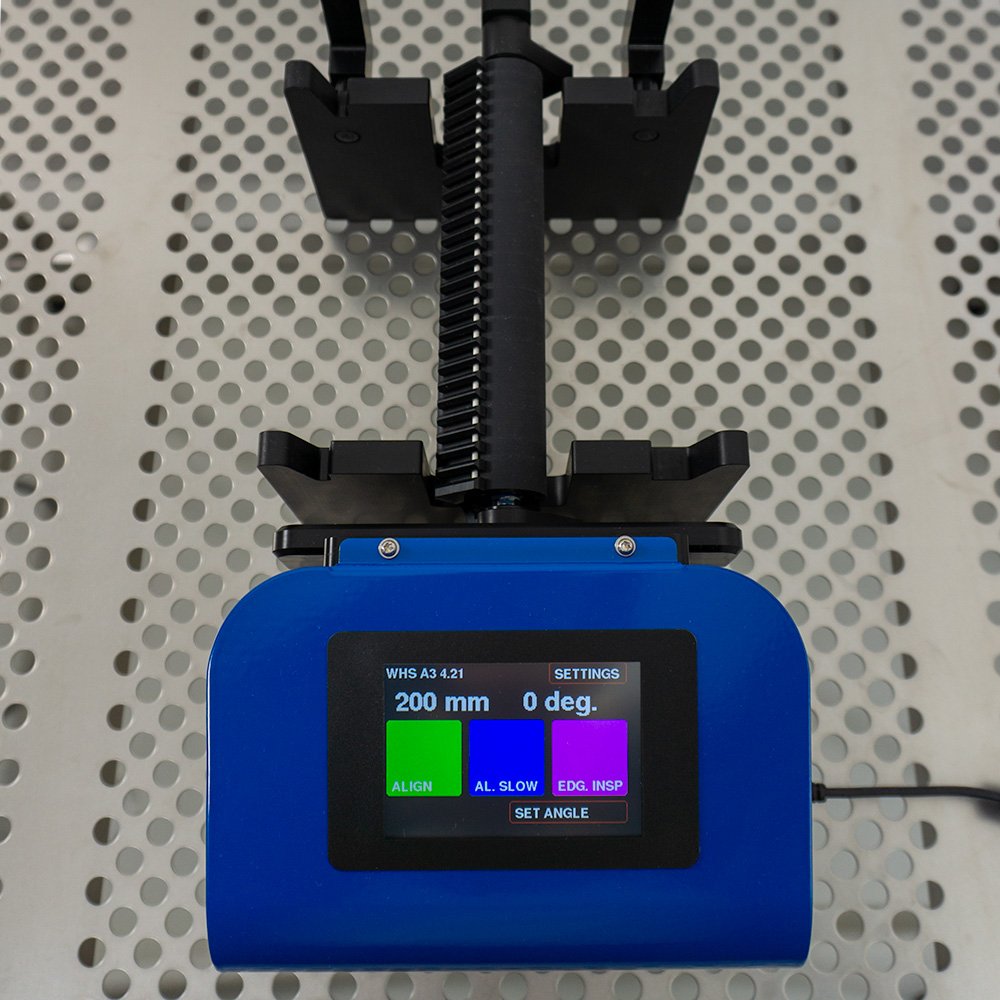

WHS-A3 시리즈는 150mm 또는 200mm 노치 웨이퍼 정렬을 위한 첨단 기술의 자동 웨이퍼 노치 정렬 장치입니다.

ESD 안전 폴리우레탄 롤러와 결합된 정밀 노치 캐치 빗 어셈블리가 특징입니다.

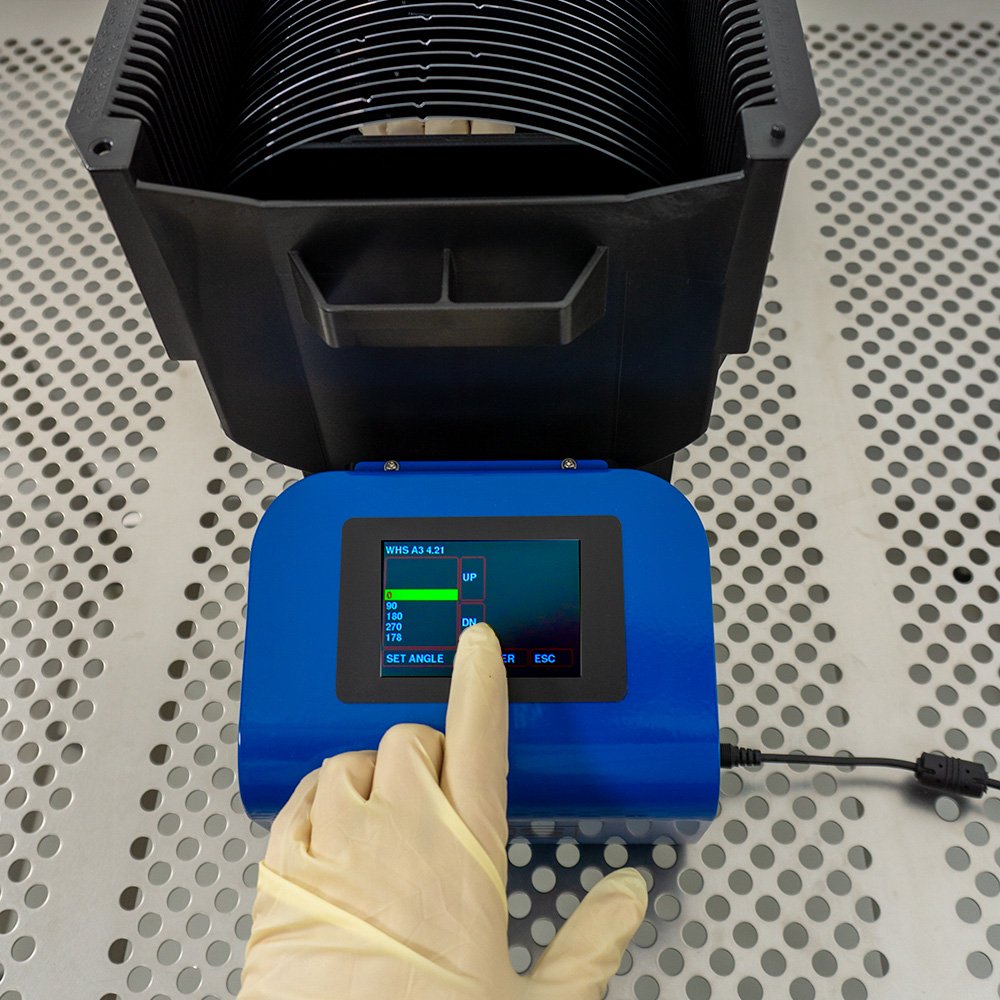

표준 정렬, 얇은 웨이퍼/복합 웨이퍼 정렬 및 가장자리 검사 레시피를 위한 터치스크린 레시피 소프트웨어입니다. ISO 클래스 3.

ESD 안전 폴리우레탄 롤러와 결합된 정밀 노치 캐치 빗 어셈블리가 특징입니다.

표준 정렬, 얇은 웨이퍼/복합 웨이퍼 정렬 및 가장자리 검사 레시피를 위한 터치스크린 레시피 소프트웨어입니다. ISO 클래스 3.

품명 |

스펙 |

납 기 |

WHS-A1-301 |

Automatic Flatfinder, Antistatic, 76mm |

2-6 weeks |

WHS-A1-401 |

Automatic Flatfinder, Antistatic, 100mm |

2-6 weeks |

WHS-A1-601 |

Automatic Flatfinder, Antistatic, 150mm |

2-6 weeks |

WHS-A1-701 |

Automatic Flatfinder, Antistatic, Multisize, 76,100,125,150mm |

2-6 weeks |

WHS-A1-801 |

Automatic Flatfinder, Antistatic, 200mm |

2-6 weeks |

WHS-A2-301 |

Manual Flatfinder, Antistatic, 76mm |

2-6 weeks |

WHS-A2-401 |

Manual Flatfinder, Antistatic, 100mm |

2-6 weeks |

WHS-A2-601 |

Manual Flatfinder, Antistatic, 150mm |

2-6 weeks |

WHS-A2-701 |

Manual Flatfinder, Antistatic, Multisize, 76,100,125,150mm |

2-6 weeks |

WHS-A2-801 |

Manual Flatfinder, Antistatic, 200mm |

2-6 weeks |

WHS-A3-801 |

Automatic Notch Aligner 8" (200 mm) |

2-6 weeks |

WHS-A4-601 |

Manual Notch Aligner 6" (200 mm) |

2-6 weeks |

WHS-A4-801 |

Manual Notch Aligner 8" (200 mm) |

2-6 weeks |

WHS-A5-301 |

Economy Manual Flatfinder, Antistatic, 76mm, Single Turn Knob |

2 weeks |

WHS-A5-401 |

Economy Manual Flatfinder, Antistatic, 100mm, Single Turn Knob |

2 weeks |

WHS-A5-601 |

Economy Manual Flatfinder, Antistatic, 150mm, Single Turn Knob |

2 weeks |

WHS-A6-301 |

Economy Manual Flatfinder, Antistatic, 76mm, Dual Turn Knob |

2 weeks |

WHS-A6-401 |

Economy Manual Flatfinder, Antistatic, 100mm, Dual Turn Knob |

2 weeks |

WHS-A6-601 |

Economy Manual Flatfinder, Antistatic, 150mm, Dual Turn Knob |

2 weeks |

재성ITS co.

경기도

안양시 동안구 호계동 555-9 안양

국제 유통단지 17동 127호

경기도

안양시 동안구 호계동 555-9 디오밸리 410호

Tel

: (031) 479-4211/2, Fax : (0504) 460-0288

1992-2023

,Jsi.co. All rights reserved

Contact us :contrabase26@gmail.com jsi@jsits.com